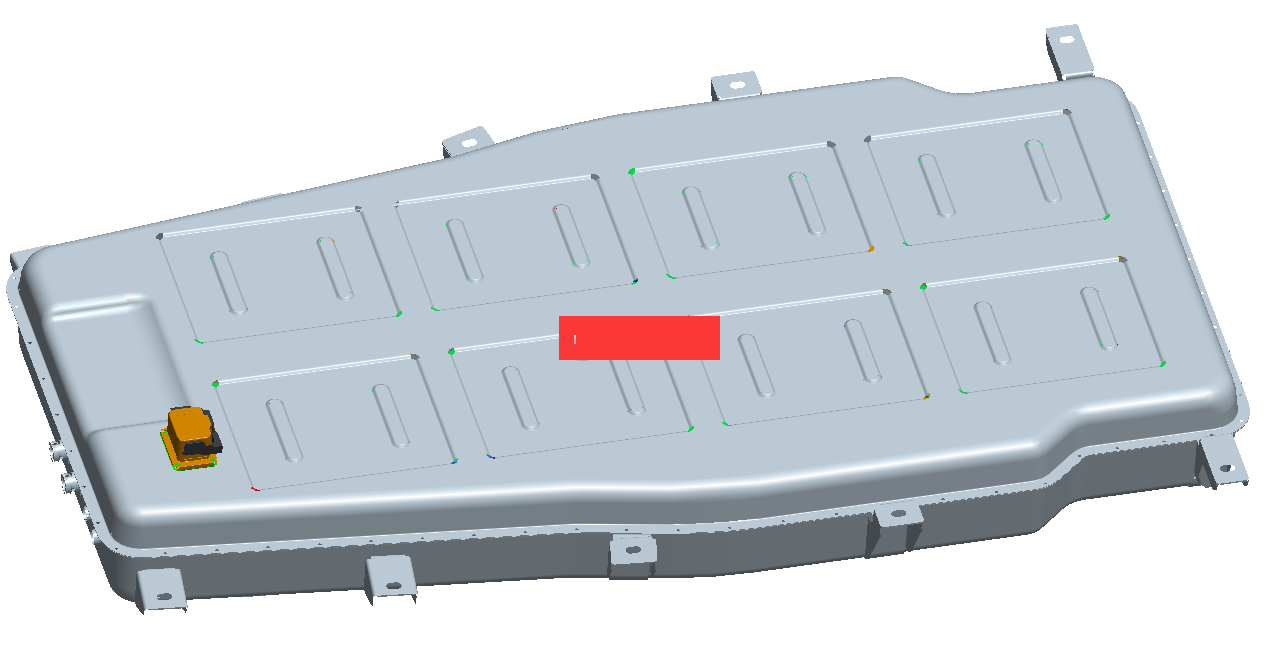

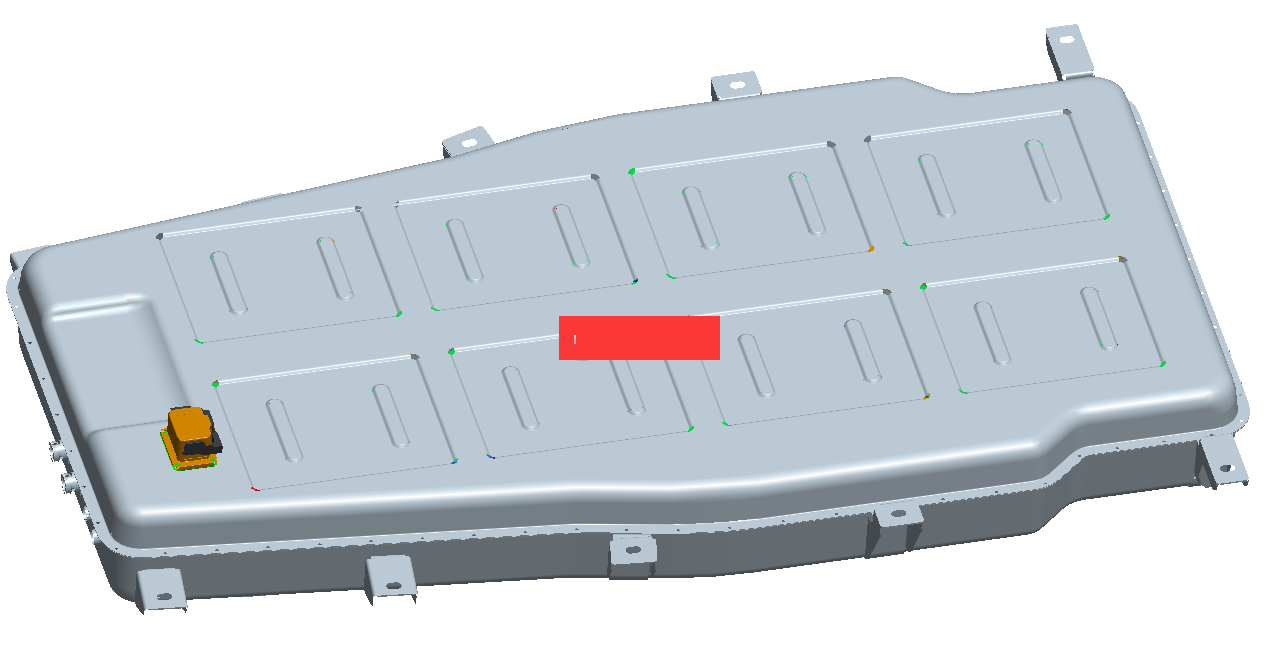

Sheet Metal Design For New Energy Vehicle Battery Box

The arrival of the sharing economy will change people's way of life and also bring about industrial transformation. Some internet companies are now investing in mutual sharing cars. Shared cars will definitely adopt lightweight, safe, energy-saving and environmentally friendly models due to cost considerations, which will become a new growth point in the automotive industry. Various automobile brands are increasing their investment in the research and development of new energy vehicles and product upgrades to meet the needs of the sharing economy. With the development and progress of technology, the charging speed and driving range of pure electric vehicles are accelerating, and it will have to replace traditional gasoline vehicles. The current requirements of electric vehicle power batteries are high, and the charging speed is high. Therefore, the quality requirements for the sheet metal processing of the battery box are very high. The battery pack will be the main component of electric vehicles, and automobile manufacturers also attach great importance to this aspect of quality.

The main principles and requirements for sheet metal processing of new energy vehicle battery boxes are:

(l) Meet the installation conditions of the entire vehicle, including dimensions, installation interfaces, etc;

(2) The insulation between the battery box and the battery module, and the insulation between the battery box and the entire vehicle;

(3) Waterproof and dustproof meet the requirements of IP54 or above;

(4) Reduce the possibility of self-discharge caused by the battery inside the battery pack. The conductive connection between batteries must be connected with copper bars to adapt to the input and output of large current;

(5) All interfaces (communication, electrical, maintenance, mechanical) are complete and reasonable;

(6) The fixation of the module inside the battery box and the fixation of the battery pack on the entire vehicle meet the requirements of vibration, rollover, collision, etc;

(7) The temperature field design is reasonable, requiring that the temperature difference inside the battery box should not exceed 5 degrees Celsius;

(8) Prohibit the accumulation of harmful or dangerous gases in the battery pack, let alone entering the passenger compartment;

(9) Some applications (pure electric vehicles) require rapid replacement.

FUERD focuses on sheet metal processing, laser cutting, and a professional team. With years of technical accumulation, our factory can provide sheet metal processing services for new energy vehicle battery boxes. With professional and comprehensive supporting processing services, you are trustworthy.